The fuel pump relay is a small but critical component in modern automotive electrical systems. It ensures a vehicle’s fuel pump receives stable and controlled power, enabling reliable engine starting and continuous fuel delivery. While often overlooked, the relay is a frequent cause of engine-no-start conditions and intermittent fuel pump failures — making it a highly searched topic among automotive technicians, repair professionals, and electronic engineers.

For electronic component distributors, the fuel pump relay is also a strong entry point for showcasing automotive-grade relays, power switching relay devices, and replacement components. This article provides an in-depth technical view of how fuel pump relays work, common failure modes, diagnostic procedures, and how to select suitable relay components for automotive applications.

What Is a Fuel Pump Relay?

A fuel pump relay is an electromechanical component or solid-state switching device that controls the power supply to the fuel pump. Instead of routing the pump’s high current directly through the ignition switch or ECU control line, the relay allows low-current control signals to switch a high-current pump circuit safely.

Key Functional Roles

- Controls the activation of the electric fuel pump

- Protects low-current control circuits (ECU, ignition switch)

- Stabilizes power delivery and reduces electrical load

- Supports safety shutdown in case of engine stall or crash events

- Ensures consistent fuel pressure for engine performance

Typical Ratings for Automotive Fuel Pump Relays

- Coil Voltage: 12 VDC

- Contact Rating: 20–40 A (typical), up to 60 A for high-performance pumps

- Contact Form: SPST or SPDT

- Operating Temperature Range: –40°C to +125°C

- Shock & Vibration Tolerance: Automotive grade

Common packaging types include ISO mini relays, ISO micro relays, and PCB automotive relays.

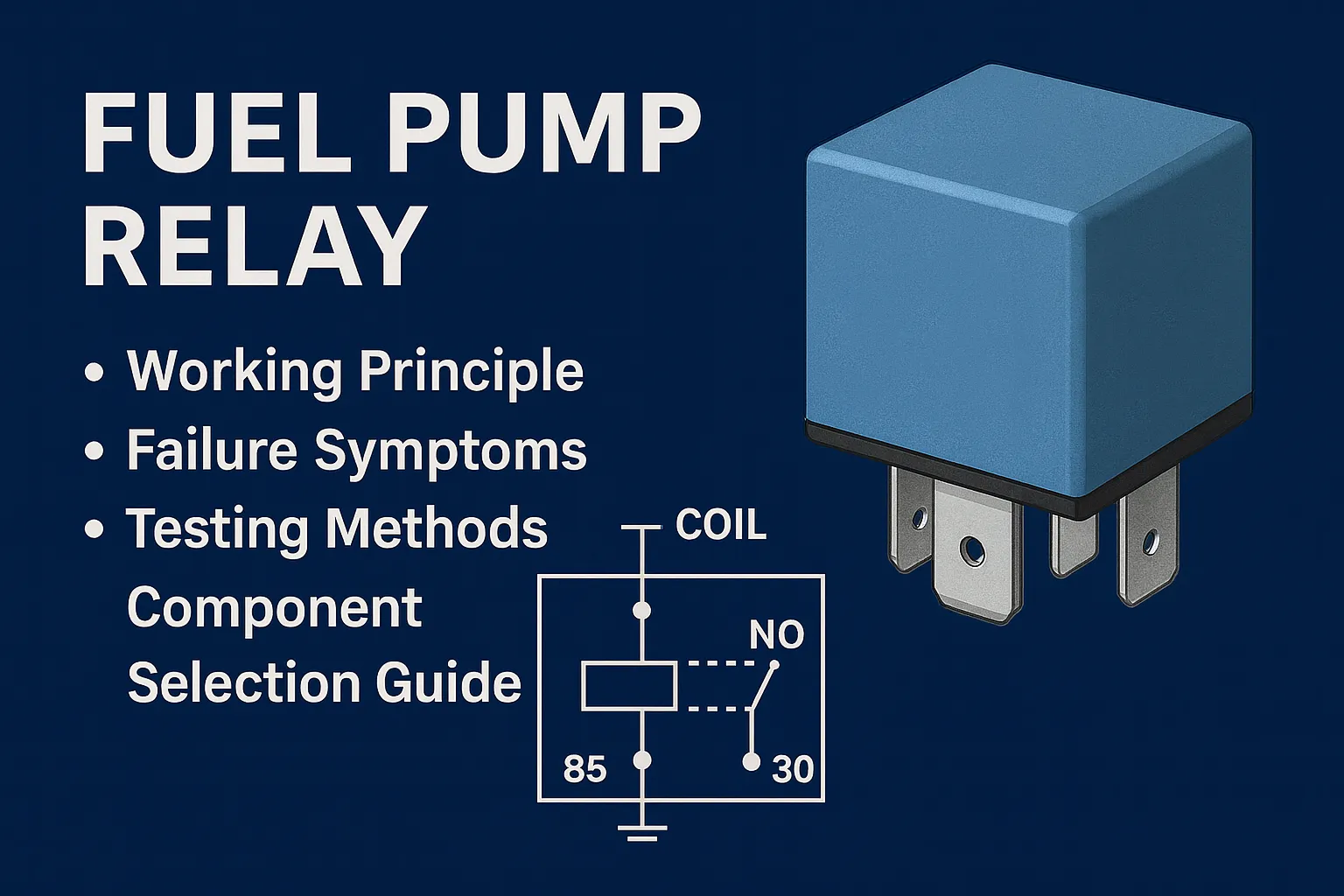

How the Fuel Pump Relay Works

A vehicle’s ECU or ignition circuit controls the relay coil, which energizes or de-energizes the relay contacts. When the driver turns the ignition key (or presses the start button), the relay briefly activates the fuel pump to prime the system. Once the engine is running, continuous control is based on ECU logic.

Basic Relay Operation

- Ignition/ECU sends low current signal to relay coil

- Coil energizes, creating a magnetic field

- Contacts close (NO → closed), delivering battery voltage to fuel pump

- Fuel pump runs and pressurizes the fuel rail

When control is removed:

- Coil de-energizes

- Contacts open

- Fuel pump stops

Safety Interlocks

Modern vehicles also integrate:

- Crash sensors that cut power to fuel pump relay

- ECU stall detection (fuel pump shuts off if engine RPM = 0)

- Immobilizer / anti-theft modules that inhibit relay activation

These safety mechanisms rely heavily on the relay’s quick response and stable performance.

Common Symptoms of a Failing Fuel Pump Relay

A failing relay may cause intermittent, partial, or complete loss of power to the fuel pump. Recognizing the symptoms helps technicians avoid misdiagnosing fuel pump or sensor failures.

Engine Cranks but Does Not Start

The most common sign. When the relay fails to close, the fuel pump never receives power, resulting in zero fuel pressure.

Intermittent Stalling While Driving

Worn contacts or thermal failure can cut power briefly, causing:

- Sudden engine stall

- Hesitation or sputtering

- Loss of power under acceleration

No Priming Sound from Fuel Tank

Typically, the fuel pump makes a humming sound for 1–2 seconds when ignition is ON. A silent tank often indicates:

- Relay not switching

- Relay coil failure

- No supply to relay

Fuel Pump Runs Continuously

If relay contacts weld together, the pump may:

- Run constantly with ignition OFF

- Cause battery drain

- Raise safety risks

Check Engine Light or Fuel Pressure Codes

Common OBD-II trouble codes related to relay failure:

- P0230 Fuel Pump Primary Circuit

- P0231/P0232 Fuel Pump Low/High Voltage

- P023F Fuel Pump Control Circuit

Relay failure is a frequent root cause.

Why Fuel Pump Relays Fail

Reliability is critical in automotive applications. Fuel pump relays operate under heat, vibration, and high current load, which accelerates wear. Here are the most common failure mechanisms.

Contact Wear and Pitting

Over time, high current switching causes:

- Arc erosion

- Surface oxidation

- Increased contact resistance

- Reduced current flow

This leads to intermittent pump operation.

Coil Burnout

Caused by:

- Overvoltage

- Excessive heat

- Manufacturing defects

Symptoms include complete non-activation.

Thermal Stress

Relays mounted near engine bay components experience:

- High ambient temperature

- Thermal cycling

- Vibration

This can deform plastic housings, soften solder joints, and reduce operating life.

Internal Mechanical Failure

Spring fatigue or magnetic weakening can prevent consistent operation.

Electrical Overload

A failing fuel pump can draw excessive current, causing the relay to overheat — a scenario where a bad pump can damage a good relay.

How to Test a Fuel Pump Relay

Testing is a standard diagnostic step during no-start troubleshooting. Below are the most reliable methods.

Relay Swap Test

If the vehicle uses multiple identical relays (e.g., horn relay, A/C relay):

- Swap with a known-good relay

- If the pump works, the original relay is faulty

Quick and widely used in workshops.

Relay Activation Test (Bench Testing)

Using a 12 V power supply:

- Apply 12 V to coil terminals

- Listen for clicking sound

- Measure continuity across switched contacts

No continuity = failed relay.

Multimeter Voltage Test in Vehicle

- Check if the relay receives ignition/ECU trigger voltage

- Check output voltage at relay contact when activated

- Measure voltage drop across contacts

Voltage drop > 0.5 V usually indicates worn or corroded contacts.

Bypass Test

Momentarily bypassing the relay (with a fused jumper wire) can confirm:

- Wiring integrity

- Pump functionality

This test must be done carefully due to fire hazards.

Choosing the Right Fuel Pump Relay (Engineering Perspective)

For distributors, this is the section where readers naturally transition from learning → purchasing. Engineers and buyers should consider several technical parameters when selecting fuel pump relays.

Coil Voltage

Most fuel pump relays use:

- 12 V coil for standard vehicles

- 24 V coil for trucks, buses, or heavy machinery

Contact Current Rating

Fuel pumps typically require:

- 15–20 A for standard vehicles

- 30–40 A for high-performance or aftermarket pumps(high-current automotive relay components)

Select a relay with 25–50% higher rating than pump current.

Contact Material

Automotive-grade relay contacts often use:

- AgSnO₂ (Silver–Tin Oxide) → high endurance, arc resistance

- AgNi (Silver–Nickel) → good general-purpose durability

AgSnO₂ is preferred for fuel pump loads.

Form Factor and Compatibility

Common types:

- ISO Mini Relay (4 or 5 pin)

- ISO Micro Relay

- PCB-mount automotive relay

Distributors can highlight pin compatibility charts for different vehicle models.

Temperature & Environmental Ratings

A high-quality automotive relay should meet:

- –40°C to +125°C operating range

- IP54+ sealing (for plug-in relays)

- High vibration tolerance

Compliance Standards

Automotive relays should conform to:

- AEC-Q200 (for components)

- ISO 7637 automotive transient immunity

- ISO 16750 environmental stress tests

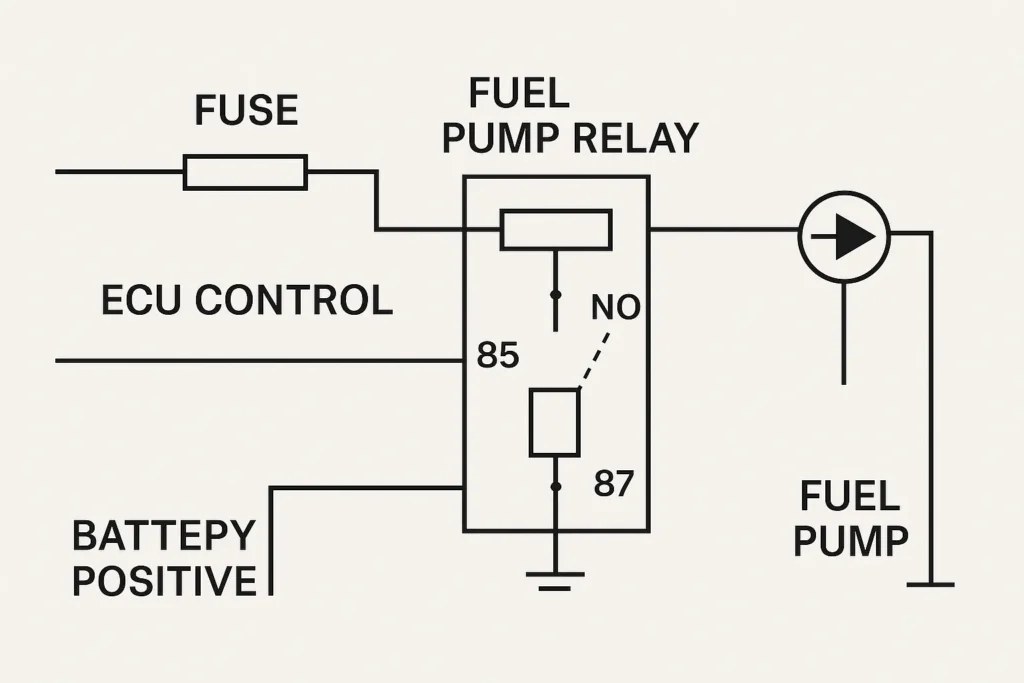

Typical Fuel Pump Relay Circuit Architecture

Although vehicle manufacturers differ, the architecture is similar across most modern fuel systems:

- Battery → Fuse → Fuel Pump Relay → Fuel Pump

- ECU → Relay Coil

- Ground connection

- Safety modules (inertial switch, crash sensor)

- Fuel pressure feedback (in some models)

This design ensures safety, reliability, and ease of troubleshoo

Replacement and Upgrades: What Distributors can Offer

A fuel pump relay is a high-volume, frequently replaced automotive electronic component. Customers often search for:

- Replacement relays

- Equivalent models

- Automotive-grade relay brands

- Relays for motors, pumps, HVAC, and lighting

As a distributor, you can highlight product categories such as:

Common Automotive Relay Types to Stock

- 40 A ISO Mini relay (most universal type)

- Micro relays for compact fuse boxes

- Sealed relays for harsh environments

- PCB relays for ECU and body control modules

Popular Fuel Pump Relay Brands

- TE Connectivity

- Panasonic

- Omron

- Fujitsu

- Song Chuan

- Tyco

- Hongfa

Recommended Automotive Relays

1. 40A ISO Mini Automotive Relay (SPST / SPDT Options)

- Contact Rating: 40A

- Coil Voltage: 12V

- Applications: Fuel pump, radiator fan, ECU power

- Features: High vibration tolerance, AgSnO₂ contacts

➡️ Ideal replacement for common fuel pump relay circuits.

2. Micro 30A Automotive Relay – Compact Type

- Contact Rating: 30A

- Coil Voltage: 12V

- Size: ISO Micro

- Applications: Modern compact fuse boxes

➡️ Suitable for newer vehicles requiring smaller footprint relays.

3. Sealed Waterproof Relay (IP67)

- Contact Rating: 35–40A

- Environmental Rating: IP67

- Applications: Off-road, truck, marine fuel pumps

➡️ Great for harsh environments and high moisture exposure.

4. PCB-Mount Automotive Power Relay

- Contact Rating: 20–30A

- Coil: 12/24V

- Applications: ECU, BCM, in-tank fuel pump modules

➡️ Designed for automotive control modules and embedded applications.

Cross-Reference Options

| OEM / Label | Equivalent Relay | Specs |

|---|---|---|

| Bosch 0 332 XXX XXX | 40A ISO mini SPST | 12V coil, AgSnO₂ |

| Omron G8HN series | Micro relay SPDT | 30A |

| Song Chuan 301 series | Automotive power relay | 40A standard footprint |

➡️ Need cross-reference support? Our team can match relay alternatives for your vehicle or project.

Conclusion

The fuel pump relay is an essential part of the automotive fuel delivery system, enabling safe, efficient, and controlled operation of the electric fuel pump. Its failure can cause major drivability issues, yet it remains a cost-effective and easily replaceable component. For an electronic component distributor, covering this topic not only educates audiences but also aligns directly with the sale of automotive relays and related products.

By understanding how the relay works, its failure symptoms, diagnostic methods, and selection criteria, engineers and procurement professionals can make informed decisions and choose reliable components that meet automotive standards. Stocking high-quality, automotive-grade relays — and guiding users through technical content — helps build credibility, increases organic traffic, and ultimately drives more conversions.