The semiconductor die at the heart of an integrated circuit is only part of what determines a component’s performance. The IC package—the physical structure surrounding the silicon—defines how well heat flows away, how signals propagate, how the device is soldered, and how long it will last in real-world operation.

Choosing the right IC package is critical in designing reliable, efficient electronics for consumer devices, industrial automation, automotive modules, medical sensors, and IoT products. While datasheets provide electrical specifications, engineers must also understand thermal resistance, parasitic behavior, solder joint reliability, PCB layout constraints, and manufacturability—all of which depend heavily on package type.

This guide explains the most widely used IC packaging types today and provides deep technical insights into thermal paths, parasitics, assembly challenges, and package selection trade-offs. For a broader understanding of IC classifications, see our Types of Integrated Circuits overview.

What IC Packaging Really Does

IC packaging is not just a protective enclosure; it gives the chip:

1. Electrical connectivity

Wire bonding, flip-chip, or solder bumping connects the silicon die to external pins or pads. The package geometry dictates parasitic inductance and capacitance, affecting high-speed and RF behavior.

2. Mechanical protection

The package shields the silicon from moisture, contamination, ESD, vibration, and mechanical stress.

3. Thermal dissipation

The package creates a heat path from die → substrate → PCB. Thermal limits often define maximum load current for regulators and drivers.

4. Manufacturability & assembly

The package determines how the IC is placed, soldered, inspected, reworked, and tested.

With these fundamentals in mind, let’s examine each major package family.

Common IC Packaging Types

DIP (Dual In-Line Package)

Through-hole, mechanically robust, large inductance

The DIP package was once the dominant IC form factor and is still used in prototyping, education, and legacy industrial control systems.

Characteristics

- Through-hole mounting with two rows of long leads

- Very easy to solder manually

- Excellent mechanical robustness

- Poor high-speed performance (long leads → high parasitics)

- Large footprint unsuitable for modern compact electronics

Pros

- Best hand-soldering experience

- High mechanical stress tolerance

- Breadboard-friendly

Cons

- High parasitic inductance

- Poor thermal performance

- Not suitable for high-density or high-frequency designs

SOIC (Small Outline Integrated Circuit)

Standard SMT package for low-/mid-pin-count ICs

SOIC packages are widely used across analog, digital, and mixed-signal ICs.

Characteristics

- Gull-wing leads with 1.27 mm pitch

- Easy visual inspection

- Good manufacturability

- Moderate thermal performance

- Suitable for general-purpose analog and digital ICs

Pros

- Easy PCB routing

- Manufacturable in all PCB fabs

- Low cost

Cons

- Limited I/O density

- Thermal performance inferior to QFN or BGA

TSSOP / SSOP (Thin Shrink Small Outline Package)

Fine-pitch SMT package with lower profile and reduced parasitics

TSSOP is essentially a higher-density evolution of SOIC.

Characteristics

- Finer lead pitch (0.65 mm typical)

- Lower height

- Lower parasitics than SOIC

- Suitable for mid-range pin counts

Applications

- MCU families

- Audio ICs

- PMIC controllers

- Interface ICs

Pros

- Compact footprint

- Good electrical performance

- Cost-effective

Cons

- Harder to hand solder

- More susceptible to bridging or tombstoning

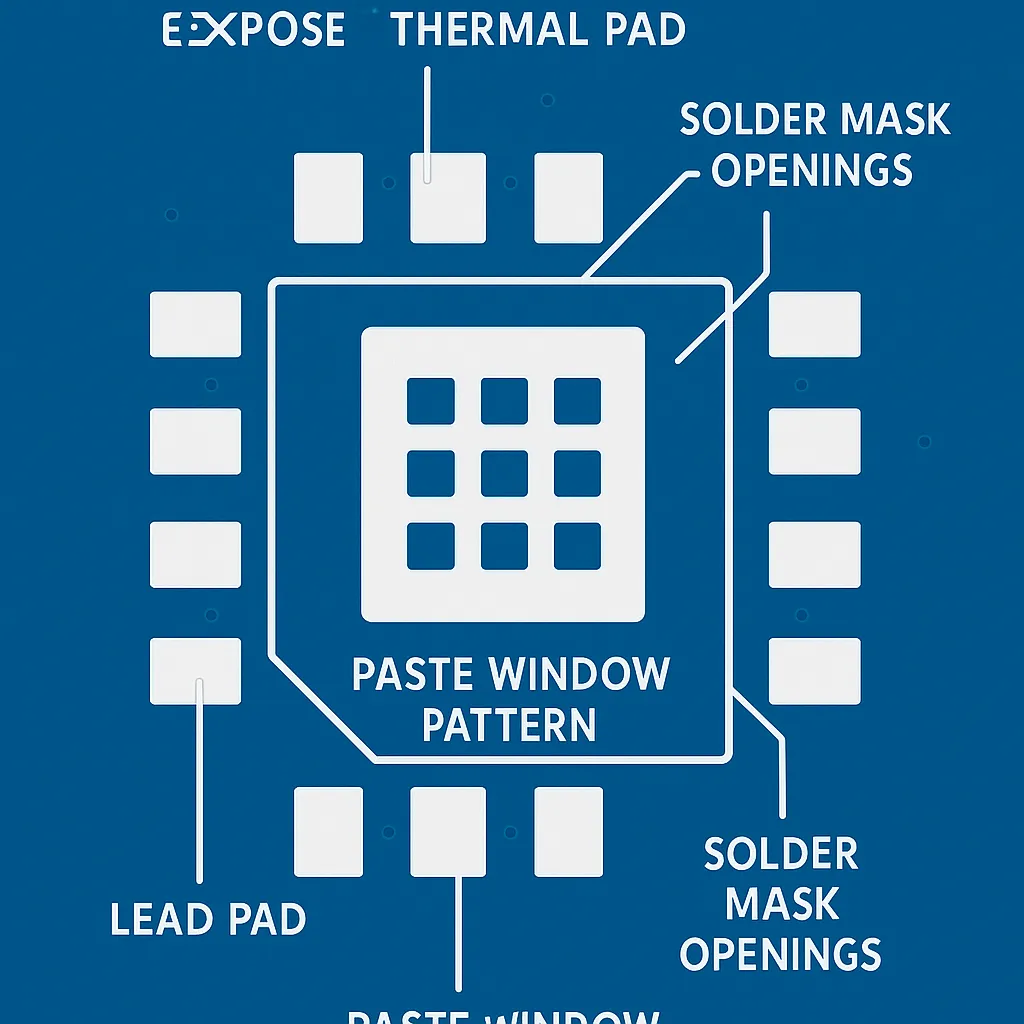

QFN (Quad Flat No-Lead)

Low-parasitic, thermally efficient, modern standard for power and RF

QFN is one of the most widely used packages for today’s PMICs, RF chips, motor drivers, amplifiers, and microcontrollers.

Characteristics

- No protruding leads → extremely low inductance

- Exposed thermal pad under die for heat dissipation

- Excellent thermal and electrical performance

- Requires precise solder paste stencil design

- Inspection may require X-ray

Applications

- Buck/boost regulators

- RF transceivers

- ADCs/DACs

- Gate drivers

- IoT MCUs

Pros

- Outstanding thermal resistance (low θJA, low θJC)

- Excellent for high-frequency and RF circuits

- Very compact footprint

Cons

- Hard for hobbyist soldering

- Bottom pad must be properly soldered

- Voiding under thermal pad affects performance

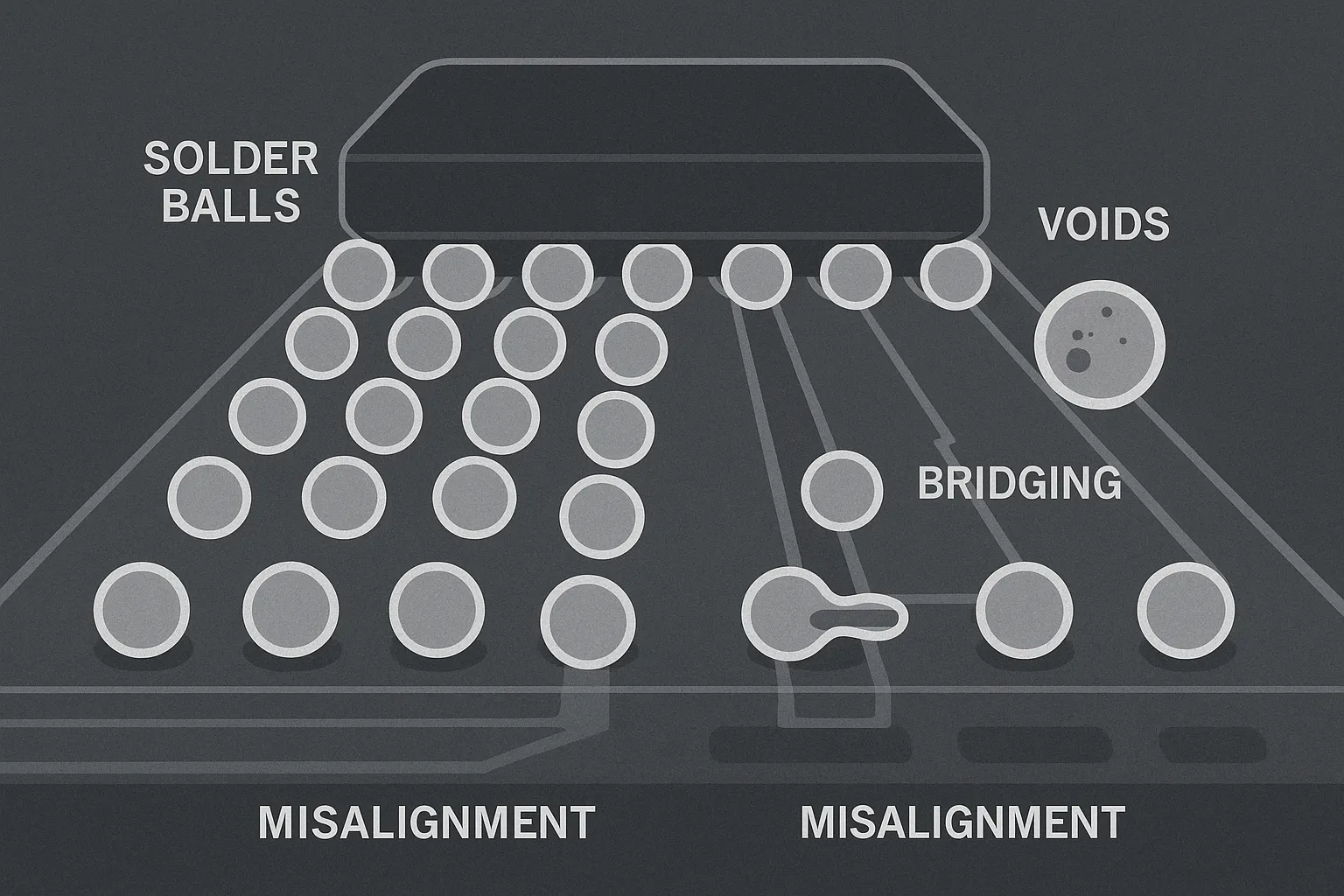

BGA (Ball Grid Array)

High-speed, high-density package for processors, FPGAs, memory

BGA uses an array of solder balls beneath the chip instead of external leads. This allows extremely high pin density and excellent high-speed signaling.

Characteristics

- Solder balls under package

- Very low inductance

- Excellent for DDR, PCIe, SerDes, USB 3.x, Gigabit Ethernet

- Requires controlled reflow and X-ray inspection

- Difficult to rework

Applications

Pros

- Highest I/O density

- Best electrical characteristics for high-speed

- Excellent thermal spreading

Cons

- Expensive to assemble

- X-ray required to inspect solder joints

- Not hobbyist-friendly

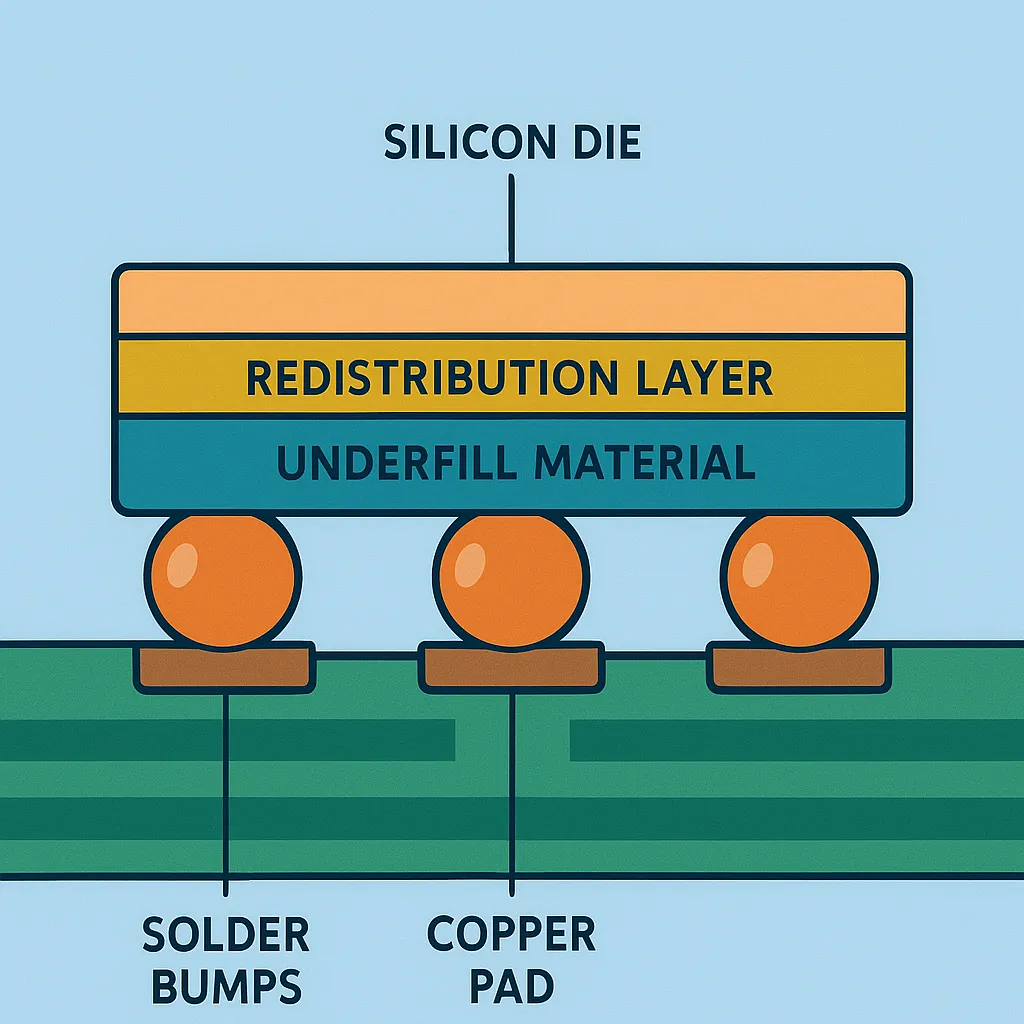

WLCSP (Wafer-Level Chip Scale Package)

Smallest possible package; used heavily in mobile and wearables

A WLCSP is essentially the bare silicon die with a redistribution layer (RDL) and solder bumps. There is no molded package, making this the smallest, lowest-parasitic IC form.

Characteristics

- Almost the same size as the silicon die

- Lowest possible parasitics (excellent for RF and high-speed)

- Very fragile mechanically

- Sensitive to PCB flex and drop shock

- Typically requires underfill

Applications

- Smartphones

- Wearables

- Low-power sensors

- PMICs and SoC subsystems

- Tiny BLE modules

Pros

- Minimal footprint

- Best electrical performance

- Low height for mobile devices

Cons

- Mechanical reliability concerns

- Must use strict reflow control

- Requires underfill in consumer electronics

Comprehensive IC Package Comparison Table

| Package | Size | Parasitics | Thermal | I/O Density | Assembly Difficulty | Best Use Cases |

|---|---|---|---|---|---|---|

| DIP | Large | Poor | Poor | Low | Very easy | Prototyping, education |

| SOIC | Medium | Moderate | Moderate | Low | Easy | General-purpose ICs |

| TSSOP | Small | Good | Moderate | Medium | Medium | MCUs, codecs |

| QFN | Very small | Excellent | Excellent | Medium-high | Medium-hard | PMICs, RF, high-speed analog |

| BGA | Compact | Excellent | Excellent | Very high | Hard | FPGAs, MPUs, DDR memory |

| WLCSP | Minimal | Outstanding | Good | Low | Very hard | Mobile & wearables |

Thermal Performance of IC Packages

Thermal behavior is one of the most important considerations in package selection. Poor thermal dissipation will reduce lifespan or cause immediate failure.

Key metrics:

- θJA (Junction-to-Ambient): heat resistance from die → PCB → air

- θJC (Junction-to-Case): heat resistance from die → package top/bottom

- Power Derating: allowable power drops as temperature increases

Thermal Comparison Table

| Package | θJA (Typical) | θJC (Typical) | Thermal Notes |

|---|---|---|---|

| DIP | 80–120°C/W | 20–40°C/W | Worst thermal performance |

| SOIC | 60–100°C/W | 15–30°C/W | PCB copper helps |

| TSSOP | 50–90°C/W | 12–25°C/W | Slim profile slightly improves airflow |

| QFN | 25–50°C/W | 1–5°C/W | Exposed thermal pad = excellent |

| BGA | 20–40°C/W | 1–3°C/W | Ball array spreads heat efficiently |

| WLCSP | 40–70°C/W | 2–5°C/W | Limited by die size, but short path |

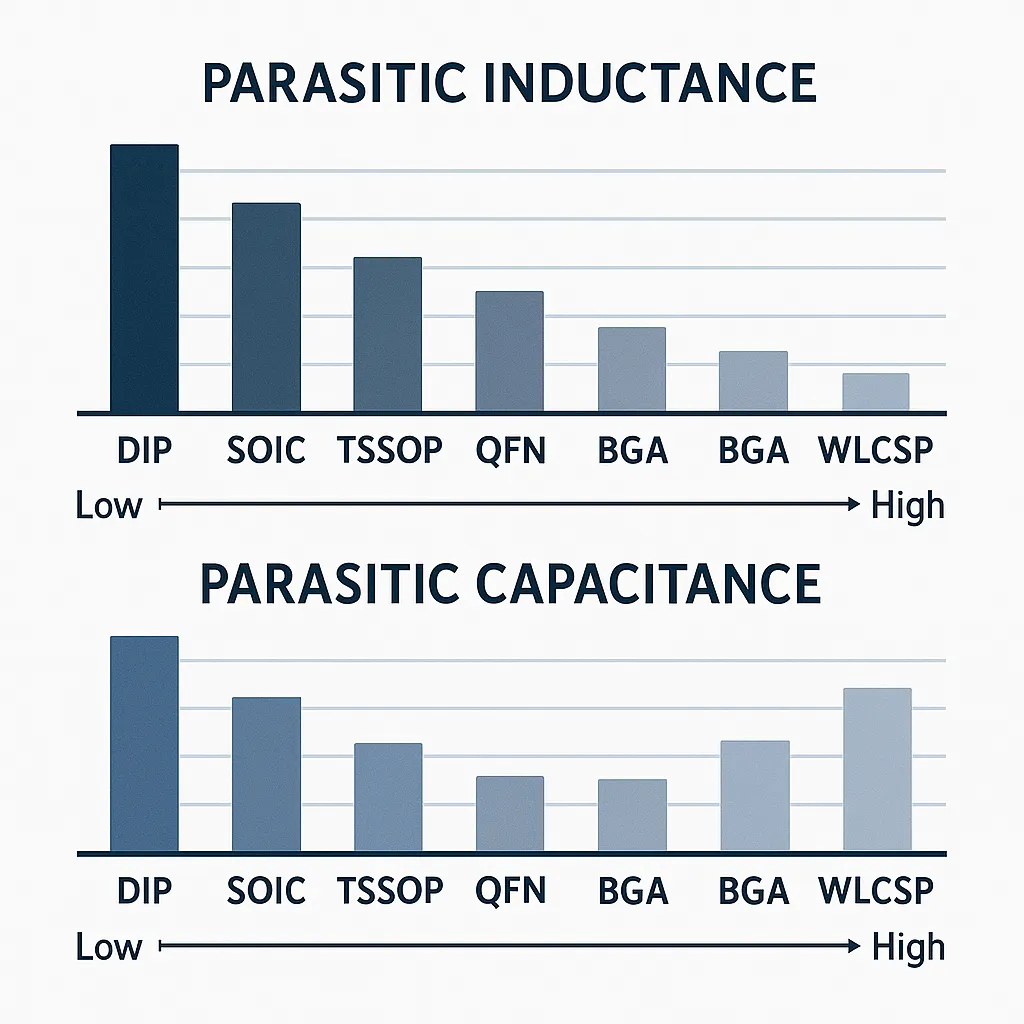

Electrical Parasitics & Signal Integrity

Package parasitics strongly influence noise, bandwidth, overshoot, ringing, and RF behavior.

Inductance (L) and capacitance (C) depend on:

- Lead length

- Pad size

- Internal bond wires or flip-chip approach

- Package geometry

Low-parasitic packages like QFN, BGA, and WLCSP improve high-speed and RF performance.

Manufacturing Considerations

MSL (Moisture Sensitivity Level)

Moisture can cause “popcorning” during reflow. Typical ratings:

- DIP/SOIC → MSL 1

- TSSOP/QFN → MSL 1–3

- BGA/WLCSP → MSL 3–5 (high risk)

Reflow Profiles

Poor reflow can cause:

- Voids

- Cold joints

- Warping

- Cracked solder balls

- Die-edge stress failures

Solder Joint Reliability

BGA and WLCSP joints are the most susceptible to:

- Vibration

- Drop impact

- Thermal cycling

Mitigation methods:

- Underfill

- Stiffeners

- Flexible PCB routing

- Symmetric copper distribution

How to Select the Right IC Package

1. Electrical requirements

- High-speed interfaces (DDR, PCIe) → BGA

- RF front-ends → QFN or WLCSP

- Precision analog → SOIC or QFN

2. Thermal load

- Power ICs → QFN / BGA

- Low-power sensors → WLCSP

3. Mechanical environment

- Automotive vibration → SOIC, QFN

- Mobile drop impact → WLCSP with underfill

4. Manufacturing capability

- Hobbyist soldering → SOIC/TSSOP

- Mass SMT → QFN, BGA, WLCSP

5. Cost targets

- Lowest cost → SOIC/TSSOP

- High-performance systems → QFN/BGA

Conclusion

IC packaging is a critical engineering choice that influences electrical performance, thermal behavior, reliability, manufacturability, and final product size. From legacy DIP devices to ultra-miniature WLCSPs, each package type offers distinct strengths and trade-offs.

By understanding package parasitics, thermal metrics, MSL requirements, and PCB layout considerations, engineers can choose the right IC package for their system’s electrical, mechanical, and manufacturing constraints.