Toggle switches endure because they do one job incredibly well: give humans a fast, reliable, unmistakable way to control electricity. By understanding how they work, the action styles available, and the contact configurations behind the alphabet soup, you can confidently choose a toggle that matches your electrical needs, environmental constraints, and user experience goals.

If you’re designing a control panel, start by clarifying the function (ON/OFF, selection, momentary pulse), match it to an appropriate SP/DP and ST/DT configuration, and then refine the choice with ratings, mounting, and ergonomics. Add guards or LEDs where safety and clarity matter. With that checklist in mind, you’ll ship toggles that are safe, intuitive, and built to last.

What Is a Toggle Switch?

A toggle switch is a manually operated electromechanical component that starts or stops the flow of current in a circuit. It does this by bringing conductive contacts together (closing the circuit so current flows and a device turns on) or separating them (opening the circuit so current stops and the device turns off). The actuator you touch is a lever, hinge, or small handle—the “toggle.” When moved into a position, it typically latches there until you deliberately move it again.

Toggle switches are actuators: they convert your mechanical motion into an electrical change of state. Functionally, they overlap with rocker switches (a see-saw style button) and are sometimes even grouped with them. But the hallmark of a toggle is the protruding lever you flick from one state to another—a simple, durable form that’s easy to identify by sight and feel. You may also see toggles described as toggle power switches or joystick switches in some catalogs.

Why Toggles Are So Widely Used

Toggle switches are among the most common electrical components because they offer:

- Clarity of state: At a glance, it’s usually obvious whether a toggle is in the ON or OFF position.

- Tactile feedback: The lever’s movement and audible “click” provide certainty that a command was executed.

- Simplicity and reliability: A straightforward mechanical design with few parts, proven over decades.

- Versatility: Sizes, ratings, and configurations exist for everything from tiny control panels to industrial machinery.

Materials, Ratings, and What They Mean

Toggle switches come in various body styles, mounting methods, and terminal types (solder lugs, quick-connect tabs, screw terminals, or PCB pins). Internally, contact points can be brass, copper, or silver, often plated (e.g., with gold or nickel) to improve corrosion resistance and performance at low currents.

Two electrical ratings matter most:

- Voltage (V) — the maximum system voltage the switch is designed to handle.

- Current (A) — the maximum continuous current through the contacts.

Always select a switch whose voltage and current ratings meet or exceed your application. Ratings may differ for AC and DC. (DC is generally harder on contacts because the arc that forms on opening doesn’t pass through zero like AC does.)

Toggle Switch Applications

Toggle switches appear anywhere a human needs fast, unambiguous control of electricity—from tiny control panels to mission-critical cockpits. Below are common domains, typical configurations, and practical notes you can use when specifying parts.

Residential & Everyday Devices

Examples: lamps and fixtures, workshop tools, countertop appliances, hobby power supplies.

Typical switch: SPST ON-OFF (maintained).

Why a toggle: tactile, glove-friendly, instantly legible state.

Notes: prioritize AC ratings (e.g., 120/230 V), use insulated boots where dust or splashes are likely (garages, patios).

Commercial Buildings & Facilities

Examples: wall plates for lighting zones, fan speed selectors, signage power, service panels.

Typical switch: SPST or SPDT ON-OFF-ON for low/Off/high fans or two-circuit selects.

Notes: consider LED toggles for at-a-glance status, clear legends, and UL/CE approvals for inspections. In janitorial areas, choose sealed or flush/flat toggles for wipe-down hygiene.

Industrial & Automation

Examples: conveyors, pumps, coolant systems, heaters, test benches, RCD/RCBO enable.

Typical switch:

- DPST to switch two lines together (e.g., live + neutral)

- DPDT ON-OFF-ON for mode selection or polarity routing

Notes: look for vibration-resistant hardware, panel bushings with anti-rotation washers, and IP-rated boots. For repetitive use, prefer silver alloy contacts and verify mechanical life. Pair momentary toggles with interlocks for “jog” operations.

Vehicles (Automotive, Off-Road, Motorsports)

Examples: auxiliary lighting, winches, air compressors, fuel pumps, intercooler sprayers.

Typical switch:

- SPST for simple accessory power

- DPDT for reversing small DC motors (window lifts, actuators)

Notes: prioritize 12/24 V DC ratings, illumination for nighttime, and guarded covers to prevent accidental activation over bumps. Use crimped quick-connects and strain relief; route wiring through fused circuits.

Marine

Examples: bilge pumps, nav/anchor lights, deck floods, electronics power.

Typical switch: SPST or SPDT ON-OFF-ON (e.g., nav vs. anchor).

Notes: insist on sealed switches, corrosion-resistant materials, and backlit/LED tips visible in low light. Confirm salt-spray suitability and IP67 where exposed.

Aerospace & Defense

Examples: avionics masters, fuel pumps, anti-ice, emergency systems.

Typical switch: guarded SPST/DPST, sometimes momentary for test/reset.

Notes: high demand for positive detent, lockout guards, and redundant labeling. Often paired with safety covers that mechanically force OFF when closed.

Lab, Test, and Instrumentation

Examples: bench PSU outputs, range selects, sensor/source A/B routing.

Typical switch: SPDT (changeover) or DPDT for differential/symmetric paths.

Notes: for low-level signals, choose gold-plated contacts to avoid intermittent readings. Prefer maintained action to document test states.

Audio, Music & Creative Electronics

Examples: pedalboard true-bypass, pickup/voice selects, synth mode switches.

Typical switch: SPDT/DPDT ON-ON; ON-OFF-ON for three-way voicing.

Notes: quiet actuation and reliable contact at low currents matter; add panel legends to avoid mid-show mistakes.

Security & Safety Interlocks

Examples: arming circuits, E-stop enables (not the E-stop itself), panel lockouts.

Typical switch: guarded SPST for “arm,” momentary for “test.”

Notes: use keyed or covered toggles where accidental engagement is hazardous; center-OFF patterns help create a safe neutral.

HVAC & Environmental Control

Examples: fan speeds, mode selects (heat/off/cool), damper jog.

Typical switch: SPDT ON-OFF-ON or (ON)-OFF momentary for jog.

Notes: mark positions clearly; consider flat toggles on flush plates for easy cleaning.

How a Toggle Switch Works

Inside, a toggle contains:

- An armature linked to the lever (the part that moves with your finger)

- One or more fixed terminals (endpoints of a circuit)

- A moving contact that bridges terminals (closed) or separates them (open)

When you flick the lever, the armature shifts the moving contact onto or away from a terminal. In a maintained (latching) design, it stays where you set it. In a momentary design, a spring pushes it back to a default position as soon as you release the lever—handy for “push-to-start,” “jog,” or “reset” functions.

Because the geometry is compact and the mechanics are robust, toggles endure frequent use, vibration, and a range of environmental conditions when selected correctly.

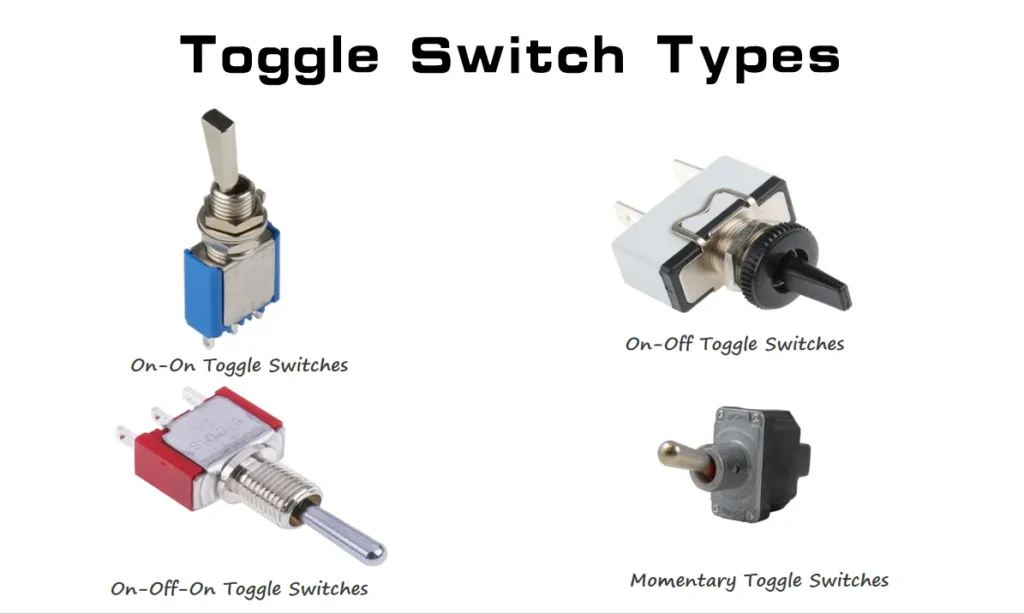

Common Toggle Switch Types

Toggle switches, as fundamental electronic parts, come in a wide range of sizes and form factors to suit different environments and applications. Their internal contacts are made from conductive metals such as brass, copper, or silver, and are often plated with gold or nickel to enhance reliability. Depending on the model, you’ll find varying contact resistances (sensitivity at low currents) and maximum current/voltage ratings.

Below are some of the most common toggle switch variants you’ll encounter.

On-On Toggle Switches (Changeover)

An On-On toggle switch is a two-position changeover device: flipping the lever connects a single input to one of two outputs, and moving it the other way transfers that connection to the alternate path. In practice, it behaves like a clean, mechanical A/B selector—ideal when you need to choose between two sources or two loads with unmistakable tactile feedback.

Because each position is maintained (latching), the selected state stays put until you deliberately flip it back, making it well-suited for audio input routing, sensor selection on test panels, or switching between redundant power rails in low-voltage systems. A common variant, written On-(On), replaces one or both maintained positions with a momentary action that springs back when released.

This is useful for tasks like temporary overrides, quick checks, or jog functions where you want the circuit to return automatically to its default path.

On-Off Toggle Switches (Positive ON/OFF)

An On-Off toggle switch is the archetypal power control: a two-position, maintained (latching) actuator that either completes the circuit (ON) or breaks it (OFF). With a firm throw and a distinctive click between positions, it gives unambiguous tactile and audible confirmation that power has been applied or removed.

This simplicity makes it the go-to choice for primary power to small tools, lamps, bench supplies, and add-on accessories. Variants may include LED indication for quick status checks, protective boots or guards for harsher environments, and different terminal styles (solder lugs, quick-connects, screw terminals) to match installation needs.

On-Off-On Toggle Switches

An On-Off-On toggle switch is a three-position changeover device that places a neutral OFF detent between two active circuits. In the upper and lower positions, the lever routes the common input to one of two outputs; in the middle, the circuit is open, providing a safe, clearly defined break. This layout is perfect for three-state controls—for example, low-OFF-high fan speeds, input A-OFF-input B on an instrument, or forward-OFF-reverse when combined with the appropriate contact configuration (often DPDT for motor polarity reversal).

Most versions are maintained (latching) in all three positions for stable operation. A related variant, written (ON)-OFF-(ON), replaces the two outer detents with momentary action so the lever springs back to center when released—useful for jog, test, or temporary override functions. Available with solder lugs, quick-connects, or PCB pins, they drop cleanly into standard panel bushings and provide crisp tactile feedback for precise, repeatable control.

Momentary Toggle Switches

A momentary toggle switch uses a spring-return mechanism so one or more lever positions are only active while you hold them. Release the actuator and it snaps back to its default detent—typically the center OFF—which helps prevent unintended continuous operation. You’ll see this expressed with parentheses in the action code, e.g., (ON)-OFF-(ON) or (ON)-ON, where each parenthesized position is momentary.

This behavior makes momentary toggles ideal for start and reset inputs, jog functions on motion equipment, and pulse commands during testing. Variants exist across SPST, SPDT, and DPDT contact configurations; for example, a DPDT (ON)-OFF-(ON) can deliver brief forward/reverse jogs to a DC motor without latching either direction.

Many off-the-shelf momentary toggles are advertised for 12 V systems and around 15 A in automotive or hobby contexts, but actual capabilities vary—always verify the datasheet for voltage type (AC/DC), current rating, and duty cycle before deployment.

Note on ratings: Many momentary toggles you’ll encounter are labeled around 12 V systems and 15 A currents in automotive or hobby contexts. Always check the specific product datasheet for the exact rating.

Other Toggle Switch Types

Toggle Switch with Cover (Guarded Toggle)

A guarded toggle adds a hinged cap or flip cover over the lever to reduce accidental activation. Lift the cover to access the switch; closing it can mechanically return the lever to OFF on some models, providing a visible “safe” state. Guards also shield the actuator from dust, oil, and snagging—ideal for aerospace, motorsport, and emergency panels where positive prevention matters as much as actuation.

Flat Toggle Switch

A flat toggle typically refers to a low-profile lever geometry or a toggle mounted in a flat faceplate for wall or machine surfaces. The sleeker actuator is harder to catch on clothing or cables and presents a cleaner look for architectural or industrial panels. You get the familiar latching feel of a toggle, but in a form factor that sits closer to the surface for improved ergonomics and easy wipe-down.

LED Toggle Switch

An LED toggle switch integrates a status light—often in the tip of the lever or within the bushing—to indicate ON/OFF at a glance. This is especially useful in noisy environments or dim lighting where tactile feedback alone isn’t enough. Options include different LED colors, independent or follow-the-contact wiring, and lens styles. Result: fewer surprises, faster troubleshooting, and safer operation.

Mini Toggle Switches (a.k.a. “Microswitch” in some contexts)

Mini toggle switches shrink the familiar lever form into a compact body for dense control panels and small enclosures. Despite their size, they’re offered in SPST, SPDT, DPDT, and momentary variants with solder lugs, quick-connect tabs, or PCB pins. They’re great for low-to-moderate currents in instruments, hobby projects, and embedded controls.

Note on terminology: some catalogs blur “mini toggle” with microswitch (snap-action limit switch). Strictly speaking, a microswitch is a different device with a spring-loaded snap mechanism and a small plunger/lever actuator, widely used as a position or safety sensor (e.g., door-closed detection). Mini toggles, by contrast, are still lever-actuated electrical switches meant for user control.

Common uses for true microswitch-style sensors (often confused with mini toggles):

- Industrial anemometers and control interlocks

- Microwave door interlocks

- Elevator and machine limit detection

- Vending machine presence/position sensing

Large/Panel Toggles

Large toggles scale up the lever and bushing for glove-friendly control, visibility, and leverage. Operators can confirm state across a panel at a glance and actuate confidently under vibration or stress—perfect for aircraft cockpits, heavy equipment, and emergency stations. Some assemblies link two levers or combine a guard for critical, sequenced actions.

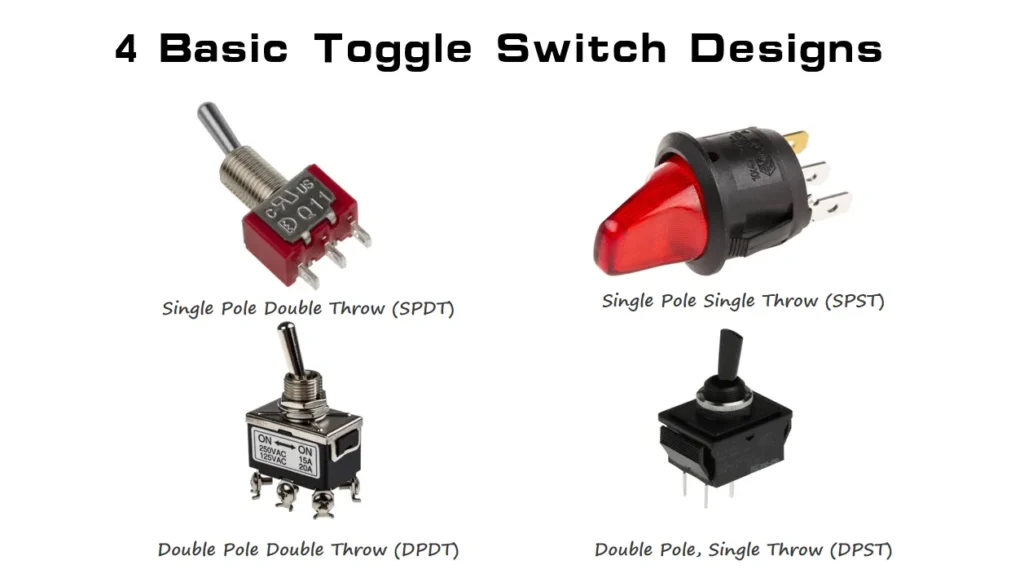

Contact Configuration: Poles and Throws

Beneath the variety of handles, boots, and bezels, most toggle switches boil down to four fundamental configurations, defined by how many independent circuits they control (poles) and how many distinct connection options each circuit can make (throws). A pole is an electrically separate path the switch controls—think “how many circuits change state together.” A throw is the number of output positions each pole can connect to—e.g., a simple ON/OFF (single throw) or an A/B selection (double throw). Combine these and you get the classic families:

SPST — Single-Pole, Single-Throw

An SPST toggle is the purest expression of a switch: one circuit, two states. Flip the lever and you either complete the path so current flows (ON) or break it so everything goes quiet (OFF). The motion is decisive and the state is obvious at a glance, which is why SPST is the staple for master power, lamp control, bench tools, and enable lines. Typically supplied as a maintained (latching) ON-OFF, it can also come as (ON)-OFF when you need a brief, held-only pulse.

SPDT — Single-Pole, Double-Throw

An SPDT toggle takes a single input (the common) and lets you steer it to one of two outputs. Picture a clean, mechanical A/B selector: in one position you feed Path A; in the other, Path B. That makes SPDT perfect for choosing between two sources or two loads, implementing two-way lighting control, or rerouting signals on test panels. Common actions include ON-ON (two active positions) or ON-OFF-ON (adds a neutral center OFF). Momentary variants—e.g., (ON)-OFF-(ON)—give you temporary selections that spring back when released.

DPST — Double-Pole, Single-Throw

A DPST toggle links two independent SPST switches under one lever, so you turn two separate circuits ON or OFF together. It’s a tidy way to bring up live and neutral at once, enable a control rail and an auxiliary line in sync, or satisfy safety rules that demand simultaneous disconnection. The feel is the same as a single ON-OFF, but internally two paths change state in lockstep. Most DPST units are maintained ON-OFF; momentary versions exist when your logic calls for a brief, coordinated action.

DPDT — Double-Pole, Double-Throw

Think of a DPDT toggle as two SPDTs ganged on one actuator: two commons, each switchable to one of two throws, moving together with the lever. This gives you symmetrical, linked routing—perfect for jobs like reversing a DC motor (swap polarity with crossed leads), switching stereo or differential signals, or toggling between redundant sources across two lines at once. Popular actions are ON-ON for straight A/B, and ON-OFF-ON when a center OFF is required as a safe neutral. As with others, momentary options are available for jog/impulse control.

When you combine action styles (maintained vs. momentary) with contact configurations (SPST/SPDT/DPST/DPDT), you can express a huge range of control behaviors, from dead-simple power gating to nuanced multi-path routing.

Selecting the Right Toggle Switch (Step-by-Step)

- Define the function.

Is it simple ON/OFF, source/load selection, forward-OFF-reverse, or a pulse/jog action? This choice narrows you to SPST, SPDT, DPST, or DPDT and to maintained vs. momentary. - Check electrical requirements.

- Voltage: What system voltage are you switching (e.g., 12 V DC, 120 V AC)?

- Current: What’s the maximum expected current? Include startup/inrush if applicable.

- AC vs. DC: Confirm the rating matches your system type.

- Consider environment.

Will the switch be exposed to dust, moisture, oil, vibration, or temperature extremes? Look for sealed gaskets, boots, guards, or specific enclosure ratings. - Choose the terminals and mounting.

- Terminals: Solder lugs for permanent wiring, quick-connects for serviceability, screw terminals for field install, PCB pins for board mounting.

- Mounting: Panel bushing with nut and anti-rotation washer is standard; flat-plate or wall plates for architectural installs.

- Human factors and safety.

- Lever length: Longer for gloves and visibility; shorter for compact panels.

- Color/legend: Clear ON/OFF markings or backlighting (LED toggles) reduce mistakes.

- Guarded covers: For safety-critical functions that must not be bumped on.

- Compliance and approvals.

If required, check for UL/CSA/CE or other regional certifications to satisfy regulations and your QA process. - Lifecycle and material.

For frequent switching or low-signal circuits, contact materials and mechanical life ratings matter. Gold-plated contacts can improve reliability at very low currents.

Wiring Basics (Conceptual)

Safety note: Always disconnect power before wiring. Follow local codes and equipment instructions.

- SPST ON-OFF: Wire the line (or the positive in DC) to one terminal and the load to the other. OFF opens the path; ON closes it.

- SPDT ON-ON: Center terminal is the common; the lever chooses which of the two outer terminals the common connects to.

- ON-OFF-ON: Similar to SPDT but with a centered OFF; great for selecting forward/neutral/reverse when paired with the right DPDT wiring for polarity reversal.

- DPST: Two input lines on one side, two outputs on the other—both circuits switch together.

- DPDT polarity reversal: Think of the switch as two linked SPDTs. Cross the leads on one side to flip polarity to a DC motor; the middle OFF (if present) acts as a safe neutral.

Labeling, color-coding, and strain relief (e.g., cable glands) help ensure maintenance is safe and foolproof.

Common Toggle Switches Manufacturers (What They’re Known For)

- NKK Switches (Japan) — Longstanding industrial-grade designs with thoughtful mechanical details (anti-rotation lever/bushing interfaces, anti-jamming structures, high-torque bushings). Strong coverage from logic-level to power-level miniature toggles; plenty of actuator and termination options for dense HMIs.

- APEM (an IDEC brand) — Rugged panel switches for harsh environments, with front-panel sealing and locking lever options. Their ranges include CECC/MIL-influenced constructions and smooth, precise toggle actions for high-spec projects.

- Carling Technologies (a Littelfuse brand) — A go-to for transportation, marine, and industrial applications needing sealing, shock/vibration resistance, and agency approvals. ST-series toggles feature IP-rated sealing strategies from the lever down to terminals.

- C&K (a Littelfuse brand) — Broad miniature portfolios with many actuator/termination permutations; widely used across medical, telecom, and instrumentation when compact, long-life toggles are needed.

- Honeywell — MIL/aerospace-oriented “MICRO SWITCH” TL lines with bonded seals and robust housings for shock, vibration, and fluid exposure; also offers guarded/locking actuation styles to prevent accidental operation.

- TE Connectivity (ALCOSWITCH) — Broad toggle families embedded in a large electromechanical portfolio; clear documentation on poles/throws and a wide distribution footprint for sourcing and alternates.

- E-Switch — Wide, parametric catalog spanning general-purpose to sealed/illuminated toggles, with quick look-up of features and footprints for fast design-ins.

- Omron — From ultra-subminiature to sealed versions, Omron’s toggles are known for careful derating guidance and handling notes that help ensure reliable field performance.

Buying tip: shortlist by pole/throw + action (e.g., SPDT ON-ON or DPDT ON-OFF-ON), then confirm AC/DC ratings, sealing/IP, and mounting/terminals. If you’ll ship globally, add UL/CSA/CE checks early.

Representative Toggle Switches Series & Models (Why They’re Popular)

- NKK M-Series Miniature Toggles — A “panel designer’s friend” with both 6 A power-level and 0.4 VA logic-level options. Mechanical touches like anti-rotation/anti-jamming features and high-torque bushings improve panel longevity. Available with multiple actuators, detents (maintained/momentary), and terminations. Great for dense HMIs and instruments.

- APEM 12000 Series — Industrial panel toggles with front-panel sealing options, locking levers, and variants shaped by CECC/MIL practices. Smooth 2-position actions plus multi-position and momentary combinations; ideal when environmental robustness and tactile quality both matter.

- Carling ST-Series — Designed for demanding environments: silicone dynamic seals around the lever/bushing, optional O-ring under-panel sealing, and terminal-end sealing per pole. Available across common circuits (ON-OFF, ON-ON, ON-OFF-ON, momentary), IP68 options, and extensive agency approvals—popular in marine/vehicle upfits.

- C&K 7000 Series Miniature — A classic mini toggle family with a deep menu of actuators (including locking options) and terminations; frequently chosen in medical and telecom builds for its size/performance balance and the series’ long market history (eases multi-year sourcing).

- Honeywell MICRO SWITCH TL Series — Aerospace/MIL-centric line with bonded seals and construction aimed at shock/vibration and temperature extremes; supports guarded and pull-to-unlock styles to prevent unintended switching. Fit when reliability and environmental resistance are non-negotiable.

- TE Connectivity ALCOSWITCH families — Broad coverage of general-purpose and application-specific toggles under a well-supported brand; helpful design content on pole/throw trade-offs and easy portfolio navigation for second-source planning.

- E-Switch Catalog Lines (e.g., TL/100/200-series families) — Emphasis on parametric filtering to quickly land on SP/ST and action combos, with sealed/illuminated and low-profile options. Efficient when you’re iterating on footprint and actuation style.

- Omron Ultra-Subminiature (A9T family example) — Tiny, board-friendly toggles where space is tight. Omron’s datasheets highlight use-within-rating and handling force guidance—important for long life in small actuators.

- Littelfuse (Cole Hersee) Heavy-Duty Toggle Switches

- 55014 (SPST, ON/OFF, 12–36 VDC)

Rugged maintained ON/OFF toggle with silver contacts; standard 15/32″ panel hole; rated 10 A @ 36 VDC for common auxiliary loads. - 55021 (SPDT, Momentary, center-return)

Momentary both directions for operator-attended control; metal actuator and silver contacts; fast install via 3 screw terminals, 15/32″ bushing. - 55025 (SPST, IP67 sealed, 25 A)

Sealed with actuator O-ring + epoxy back end; handles 25 A @ 12 VDC (15 A @ 24 VDC); standard 15/32″ mount with 14 AWG leads—ideal for wet/dirty environments. - 55033 (SPDT, Momentary ON-OFF-ON)

Return-to-center in both directions for safe jog/raise-lower actions; heavy-duty ratings 25 A @ 12 V, 15 A @ 24 V, 10 A @ 36 V with corrosion-resistant silver contacts.

- 55014 (SPST, ON/OFF, 12–36 VDC)

Frequently Asked Questions About Toggle Switches

Q: Is a higher-rated switch always better?

A: Not necessarily. Overspec’ing is generally safe, but very high-current switches can be physically larger and less pleasant to operate for small signal control. Aim to meet or modestly exceed your requirements.

Q: Can I use an AC-rated switch for DC?

A: Only if the datasheet provides DC ratings. Don’t assume AC ratings translate to DC; contact wear and arcing can be very different.

Q: What do the parentheses mean in (ON)-OFF-(ON)?

A: Momentary positions. The lever springs back to the non-parenthesized position when released.

Q: Are mini toggles the same as microswitches?

A: The terms get blurred in some catalogs. Mini toggles are compact lever actuators; microswitch more properly refers to a snap-action switch used for precise detection. In practice, you’ll see “mini toggle” used for small panel toggles and “microswitch” used for limit/position sensing—even though some sellers mix the labels.

Q: What’s the difference between SPDT and DPDT for motor control?

A: SPDT can route one circuit to either of two outputs—useful for logic signals. DPDT gives you two linked SPDTs; that lets you swap a motor’s polarity across two wires, enabling forward/reverse with one lever.